Monitoring fuel pumps on trucks

and preventing fuel thefts

Country: Gomel, Belarus

Industry: petroleum industry

Customer: Belarusneft-Trans

Operations: transportation of petroleum and its derivatives

Integrator: Wialon Operator (LLC “NewApex”)

Equipment: Wireless tilt angle sensor Escort “DU-BLE”

Customer’s objective: control over oil transportation

Belarusneft-Trans is an affiliated company of the Production Union “Belarusneft” (a state-run oil company). Belarusneft-Trans’ main activities include transporting oil and its derivatives from warehouses to fuel stations.

In 2019-2020, Belarusneft started implementing a new system for monitoring operations with fuel. Earlier such operations were the responsibility of the warehouse and gas stations operators. However, nowadays the drivers have to take care of 90% of such operations. The main objective for the deploying the monitoring system was to increase the efficiency of the operation.

Also, the company’s management decided to spare their employees of working at heights: the drivers and operators used to have to climb on the tanks to open the hatches. Nowadays, the loadings and offloadings of the petroleum and its products are carried out using a special pump box (a loading hub) that can be found on every truck.

This system also required a reliable means to monitor the operations with fuel and oil derivatives at every stage of haulage. Therefore, Belarusneft-Trans, along with other affiliated companies of Belarusneft, undertook to implement extra solutions. Among such were: using a GPS tracking platform, a surveillance system and obligatory sealing the equipment before dispatching every truck.

To further improve the efficiency of the effort, it was necessary to find a solution that would help monitor every instance the loading hub was opened when outside special zones and prevent unsanctioned fuel offloadings and thefts.

Monitoring on the move

Wialon Operator, an integrator in Belarus, offered the customer mounting tilt angles sensors on the pump hubs that would report to the monitoring platform every time the hub was open. After some consideration, Belarusneft-Trans opted for the wireless tilt angle sensor Escort DU-BLE.

The device is quick to install since there is no need for cable management. It is also easy to configure via a mobile app. Thanks to Bluetooth Low Energy technology, the sensor’s battery can last several years. Absence of cables makes it impossible to disrupt its work by causing damage to the wiring. The sensor is compatible with various GPS tracking devices and platforms, such as Wialon for example.

Installation on the trucks

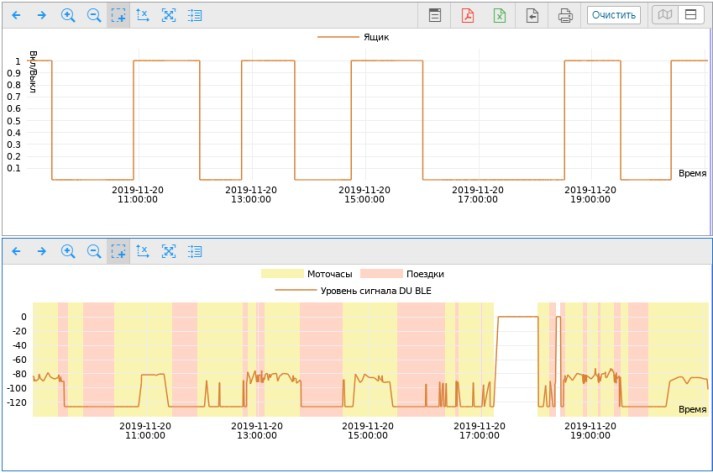

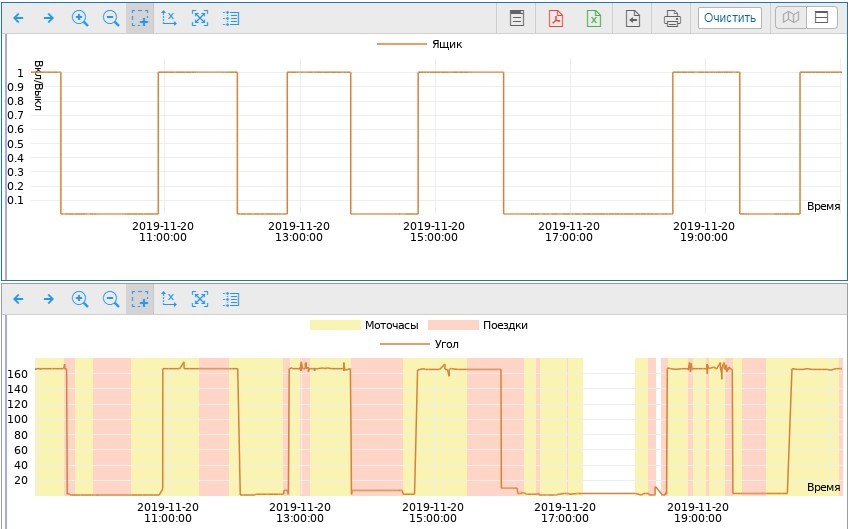

Escort DU-BLE sensors are mounted inside the pump boxes. When the lid is open, the angle reported by the sensor changes. This is further transmitted by the device to a GPS tracker and, subsequently, to the monitoring software ‘Transport’ (a program for dispatches).

Using charts and reports, one can easily trace down every instance the pump box on every truck was opened or closed and see the context: when and where it happened, if the engine was running, etc. This ensures that all requirements are met during the operations and helps assess the labor efficiency and, most importantly, spot any employee’s unsanctioned actions.

Results

According to Belarusneft-Trans, the above-mentioned monitoring system has proven to be quite efficient in preventing the drivers from committing fuel thefts. Right after its deployment, during the tests, the sensor was quick to report a theft attempt on one of the trucks.

As result, Belarusneft-Trans ordered more DU-BLE units to be installed on the rest of their oil trucks.