Reliability in everything we do

The most vulnerable link in the transportation logistics systems is improper or unreasonable use of transportation vehicles. Such negative effects lead, as a rule, to the overall decrease in productivity of the working process and, consequently, to the growth of unjustified costs.

Equipment of «Escort» brand is designed specially for the areas where the transportation vehicles profitability has to be determined, or where the financial costs of improper use have to be reduced. Production organization and quality control are carried out in compliance with the requirements of the quality management system ISO 9001-2015.

All «Escort» products underwent preliminary testing under real conditions and are perfectly integrated with various systems of transport monitoring.

«Escort» guarantees the highest productivity of equipment within the whole period of exploitation.

Select the device

EQUIPMENT

CREATING ABSOLUTELY NEW PRODUCTS

Qualifications of our engineers and developers allow us to make equipment not only for standard tasks in the sphere of transport telematics, but also in compliance with the business needs of the automobile fleet owners.

If you need a non-standard solution, you can send us your requirements specification, or address any questions to our specialists.

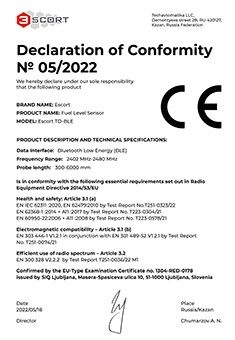

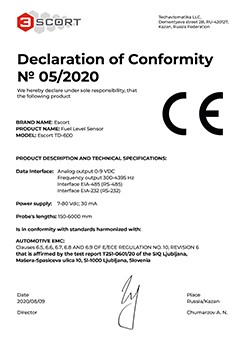

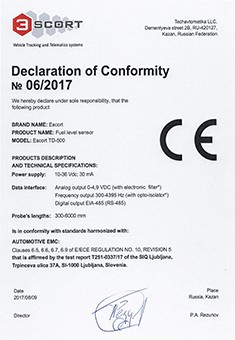

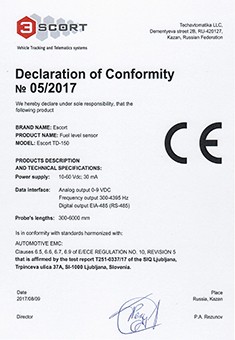

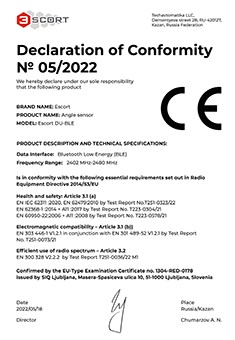

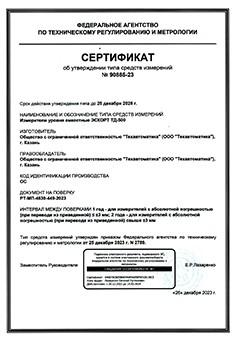

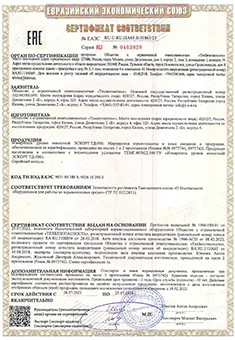

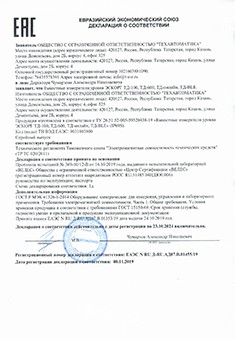

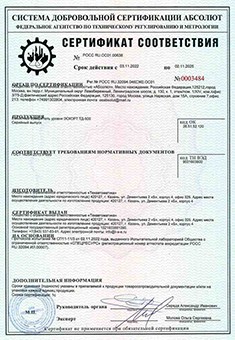

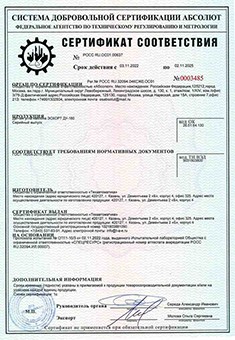

SEND A TASKLICENSES AND CERTIFICATES

in all their characteristics. SEND A QUERY FOR A TEST