Fuel monitoring helps optimize fleet’s operating costs

Country: Russia

Industry: transportation and logistics

Integrator: Ural Innovations

Customer: Komos Group (agricultural holding company)

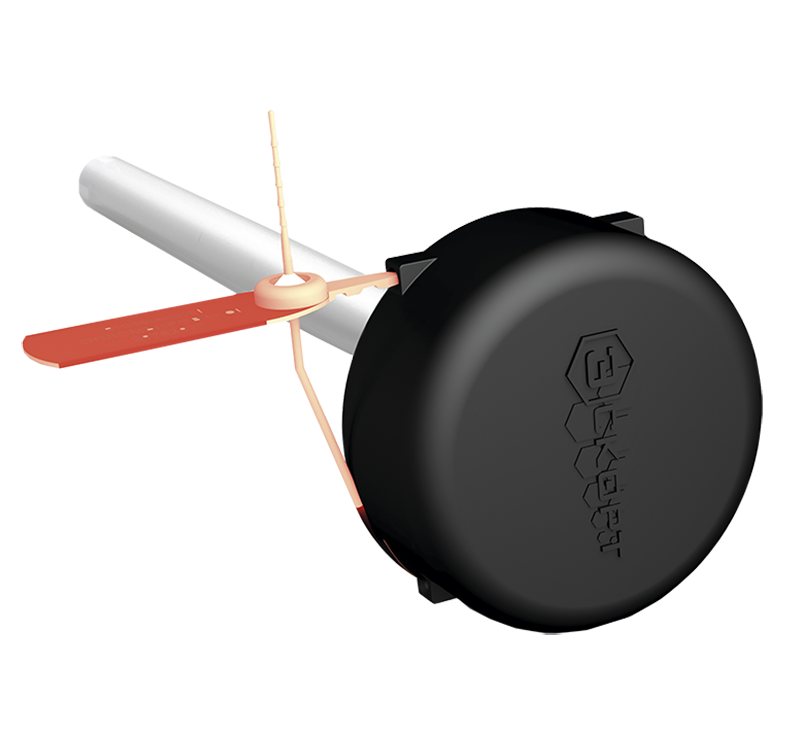

Equipment: Wireless fuel level sensor Escort TD-BLE

Anton Turkin, CEO at Escort Monitoring Systems

Many companies and organizations have to face thefts committed in one way or another. The drivers can steal the fuel from the tank, cheat with fuel cards, and use a vehicle for personal gain.

All this results in financial losses because of the misuse of fuel, wear and tear of vehicles and inefficiency of operations. Anton Turkin, CEO at Escort Monitoring Systems, gives the Komos Group’s case as an example of that the wireless fuel level sensors can help address the labor discipline issues and reduce fuel costs.

Customer

KOMOS GROUPD LLC - one of the largest agricultural holdings in Russia.

The main article on their list of expenses is the fuel costs: up to 190M per year. And it was impossible to track the actual use of fuel. Moreover, the company also had to live with the idea of the drivers’ cheating since for the majority of them the fuel in the corporate tanks is just another way to make extra money.

Customer’s goal: Komos Group to optimize the operating costs of its fleet

To reduce their fleet’s costs, the company’s management decided to keep track of the actual fuel consumption and deploy a comprehensive monitoring system. The Escort’s wireless fuel level sensors Escort TD-BLE became their choice.

The sensors were installed on the company’s 150 vehicle fleet stretched across Russia. Those were reefers and trucks with tanks for milk. Ural Innovations was the company in charge of the project. The company specializes in IT and telematics solutions for GPS/GLONASS monitoring.

Solution: install Escort fuel level sensors TD-BLE

How capacitive fuel level sensors TD-BLE work

The fuel level sensor measures the level of the fuel in the tank. It has two tubes that are placed inside the latter. They measure the dielectric permittivity of the liquid between themselves and register any changes in its level. The level data is then processed and transmitted to a GPS tracking device. This way of monitoring essentially provides means to control the fuel consumption, which is the objective of any fleet manager.

Usually, the GPS tracker is installed in a vehicle’s cabin and the sensor is connected to it by a cable. However, the wired sensors have several drawbacks: the installation and cabling takes up to three hours, they are easy to sabotage and it is easy to break the terms of their warranty. Overall, installing and using them can be a headache.

Escort company was among the first to identify the need for a better solution and came up with an innovation - wireless Bluetooth fuel level sensors. Its wireless nature is the main advantage of the TD-BLE: no need to worry about cabling and damage to wires.

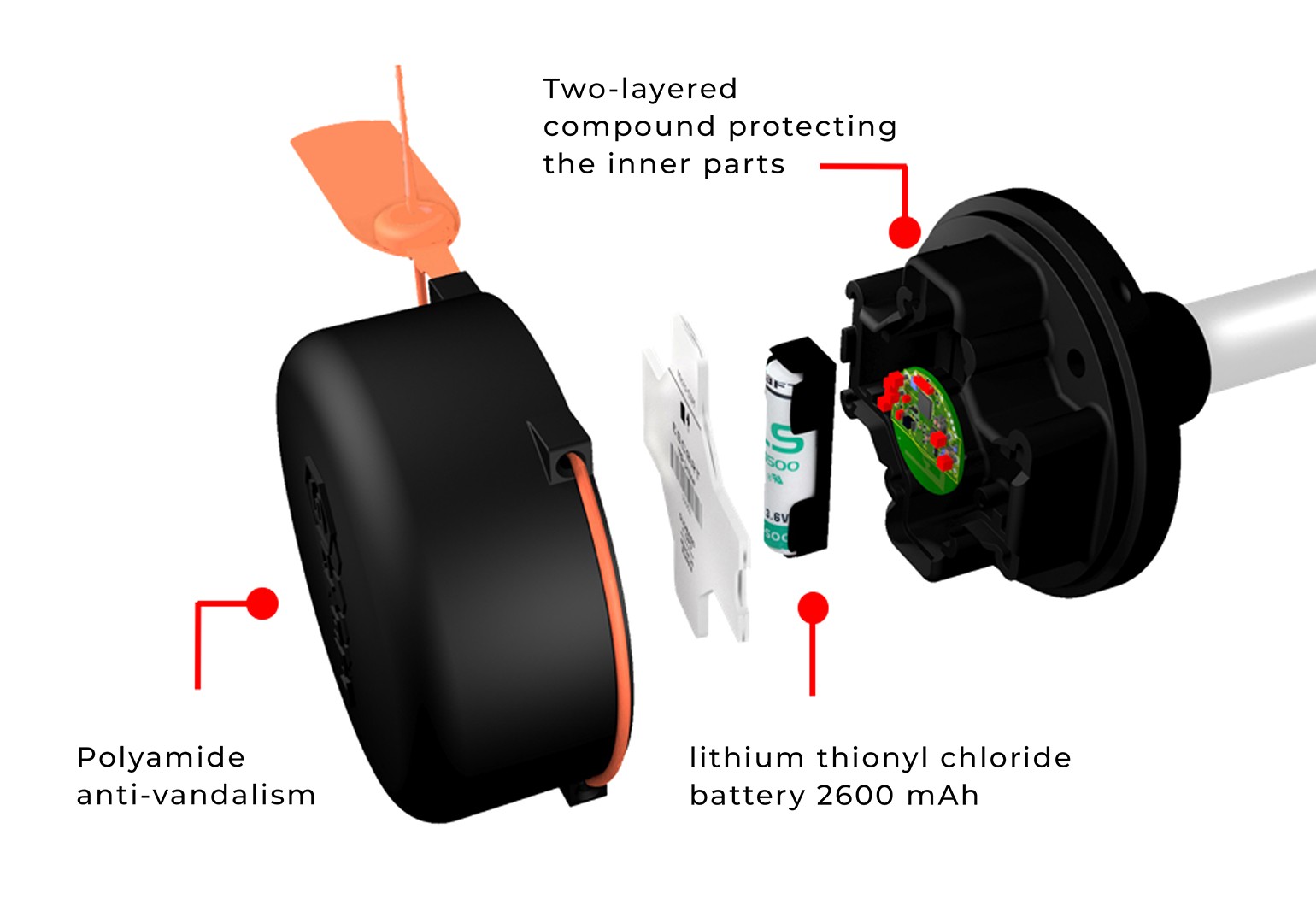

Escort TD-BLE wireless sensors: features

- The level is measured by the sensor every 10 seconds, the data packages are transmitted every 5 seconds in the advertising mode

- The operating distance - up to 10 meters (this can reach up to 100 depending on the circumstances)

- One battery can last for the average of 7 years

- The device is easy to configure via a mobile app

- The sensor can be installed within 1 hour

Even if somebody interferes with the sensor’s work, this will not go unnoticed by a GPS tracker and the monitoring platform. The TD-BLE fuel level sensor can detect any attempts to steal fuel even the most covert ones.

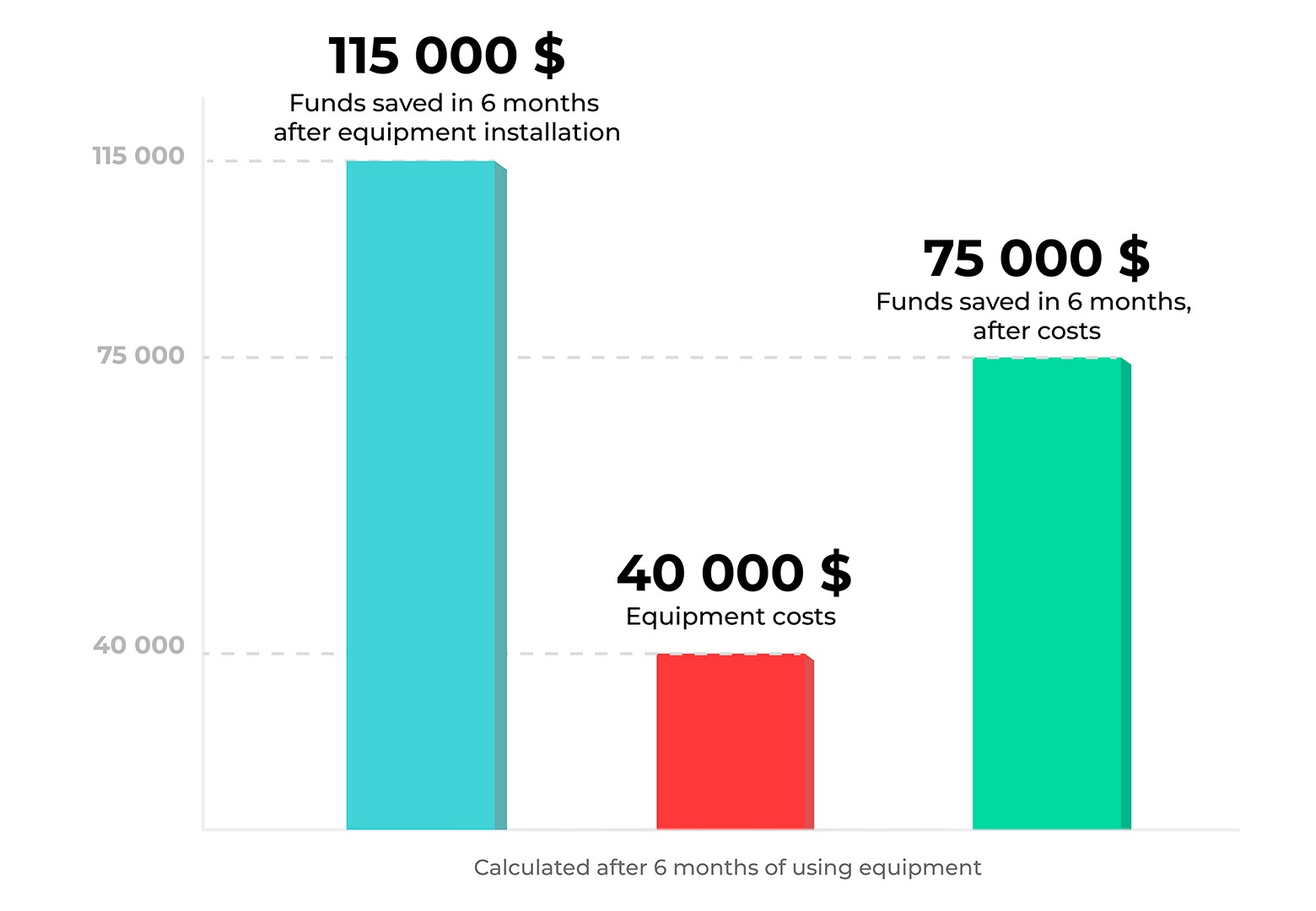

Saving up to $75k in 6 months

The installation of the wireless fuel level sensors on 150 vehicles of the KOMOS GROUP significantly reduced the fuel costs.

- The equipment and services expenses amounted to around $40k

- The total of the funds saved amounted to almost $75k after costs and expenses

Aside from preventing thefts, installing the sensors and other telematics solutions help ensure that the drivers stick to their routes and timetables and become less prone to violating the discipline.

Other ways to reduce costs

Aside from installing the fuel level sensors, it is always a good idea to implement other means of satellite and wireless monitoring.

- For example, angle sensors are designed to monitor the works of such machinery parts as crane booms, excavator arms, dump truck beds, cement mixers or garbage truck manipulators. They help avoid unnecessary idling or misuse of the assets.

- Temperature and lighting sensors help monitor the state of refrigerator trucks, which is vital for the haulage of produce and other perishable and frozen goods.

Currently, Escort sensors are used by integrators in around 86 countries across the globe. They help monitor and control fuel, safety of transported goods and operations of different types of machinery. Wireless sensors make this even easier. These are the main advantages of such devices:

easier to install

and configure

lower risks

damage

lower risks

of sabotage

more control over every

unit in a fleet

We will be glad to help you reach your goals

Escort company has been manufacturing and installing the telematics devices for over 16 years helping its customers maximize the performance of the fleets. By now, it has sold up to 500 000 sensors to more than 600 integrators all around the world. Among Escort’s customers are such huge companies as RUSAGRO, MIRATORG, «Krasny Vostok», Avangard Agro, etc.

If your drivers cheat and you want to avoid that and improve the efficiency of your fleet and, subsequently, the performance of your company, Escort Monitoring Systems is ready to provide you with samples for test runs.