Wireless fuel monitoring and control

on stationary tanks

Country: Ukraine, Zaporizhzhia Oblast, Mikhaylovsky district, Pryshyb town

Industry: agriculture

Year: 2020

Customer: Mikhaylovsky Rayagrosnab

Integrator: DAGAMA

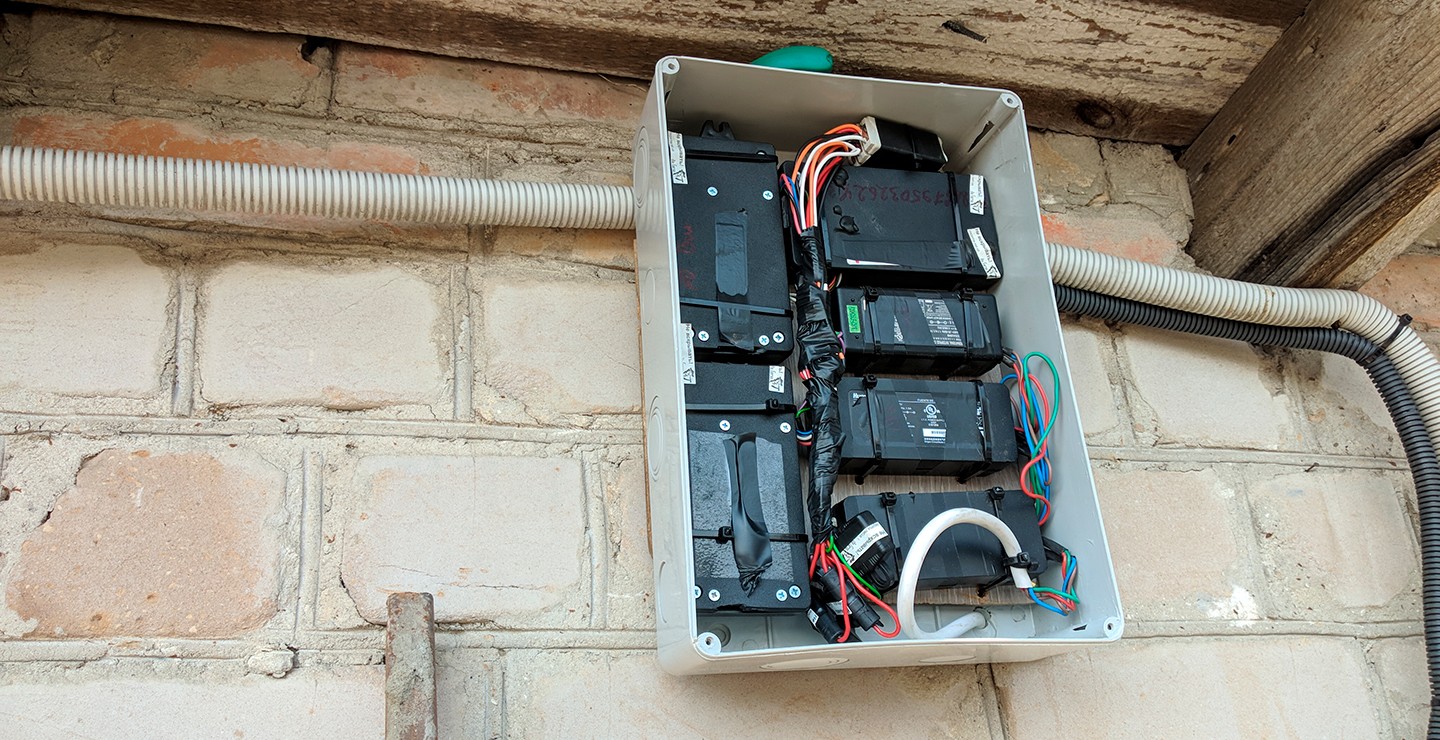

Equipment: wireless fuel level sensors Escort TD-BLE

Customer’s goal

Mikhaylovsky Rayagrosnab is a company that grows, cultivates and sells crops. All this is done by using advanced agriculture machinery and technologies that help automize processes.

The company’s fleet counts with 39 machinery units.

To constantly supply them with diesel, Mikhaylovsky Rayagrosnab has several stationary tanks. Those are big storage units with varying total capacity of 10 000, 16 000 and 25 000 liters that are located both above and under the ground.

At some point, the management of the company decided that in order to improve the company´s financial performance, they needed to tighten the control over the fuel dispensing on the tanks.

Thus, their needs were:

- to do precise tanks calibrations;

- to closely monitor the fillings, drains and the current level of diesel in the tanks.

The company’s managers turned to DAGAMA company - one of the most experienced integrators of various technologies that work with many agricultural companies in Ukraine.

Implementation issues and solutions to them

From the very beginning, this project was anything but standard. Several issues were quick to present themselves before the integrator:

- The storage tanks were located quite far from the dispensing station

- Mikhaylovsky Rayagrosnab’s management was against using any wired equipment

- The tanks located underground were hardly fit for installing wireless sensors

To overcome these obstacles and successfully secure the project, the integrator opted for implementing TD-BLE fuel level sensors and some extra equipment that would enhance the sensors’ operating range.

Naturally, when installing Escort TD-BLE sensors, you don't need to worry about cabling. Moreover, thanks to its Bluetooth Low Energy mesh, the sensor can run on one battery for up to 3 years before it needs to be replaced. The sensors are easy to install and configure via a mobile app.

Thus, the customer gets a reliable tool for fuel control and saves funds on the installation and maintenance because there will be no issues with sabotage or wear and tear of the cables.

To improve the quality of the signal and its range, DAGAMA technicians also installed the BLE-RS485 interfaces. Thus, it became possible to set up a stable wireless connection between the dispensing station and the tanks in spite of their metal encasing.

Example: TD-BLE use

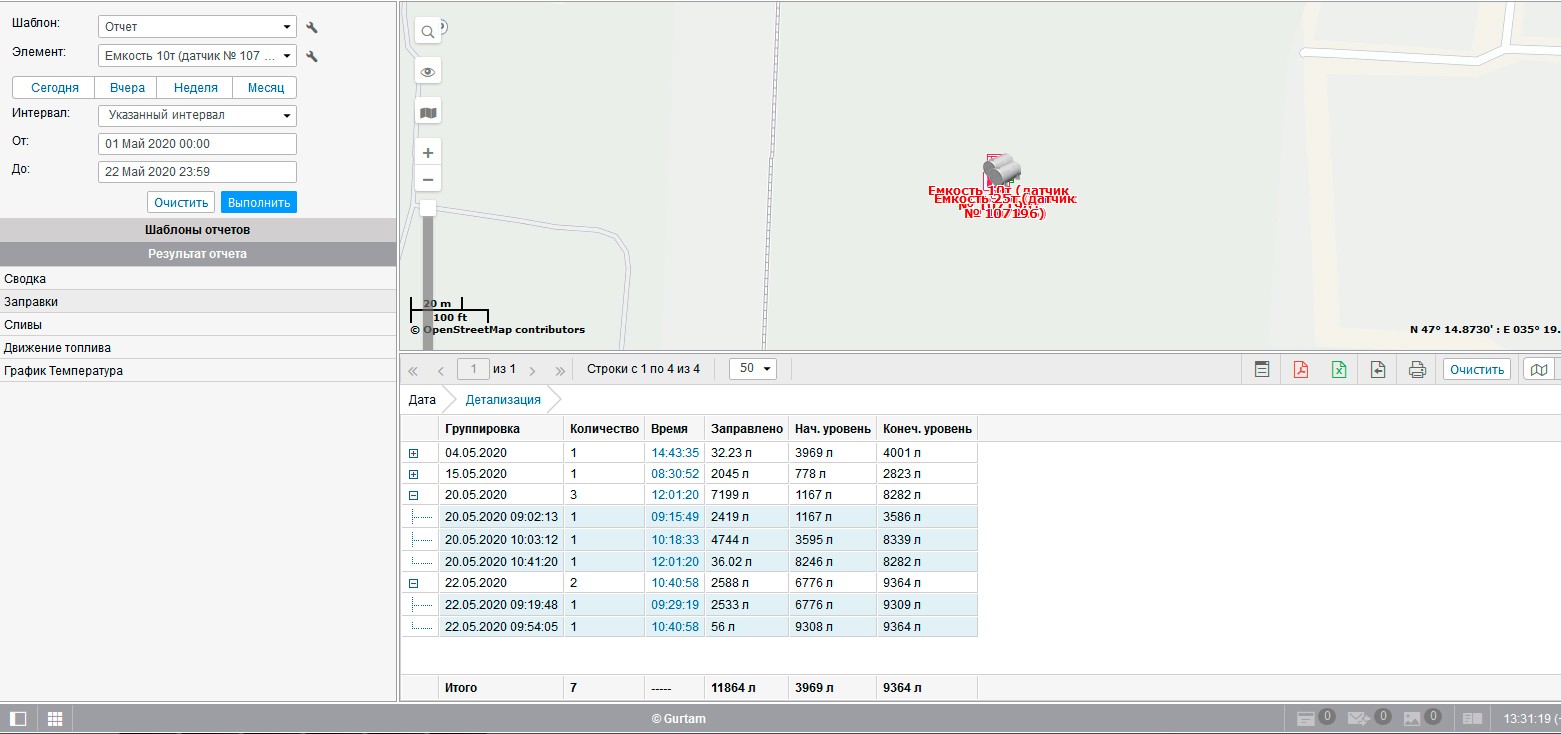

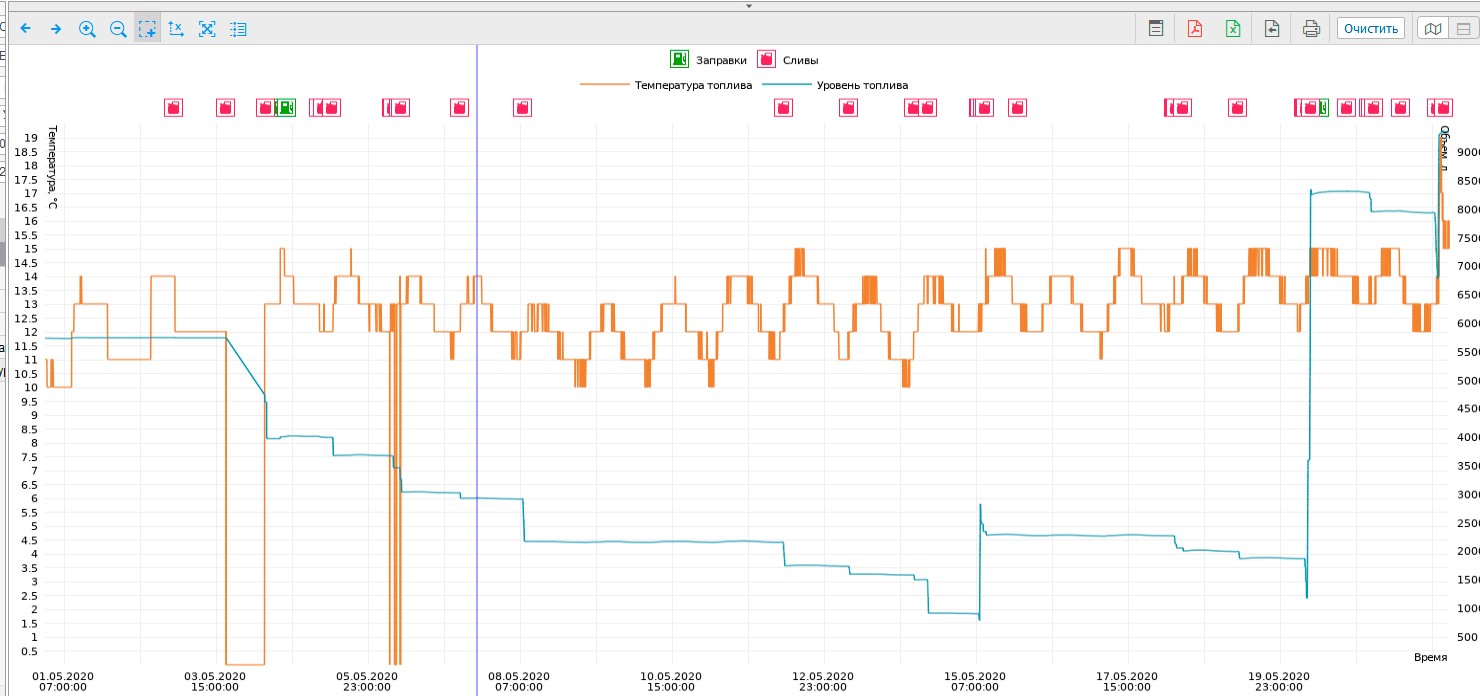

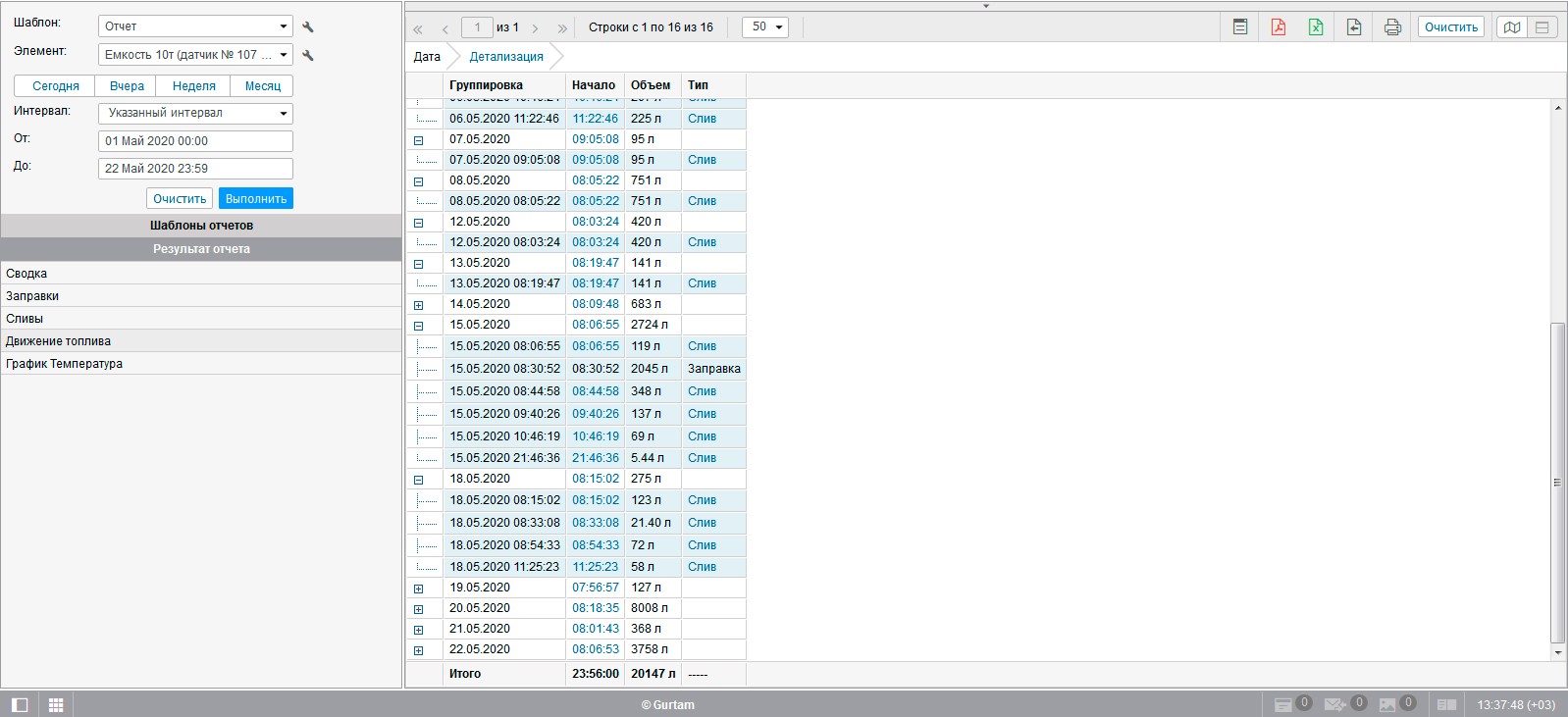

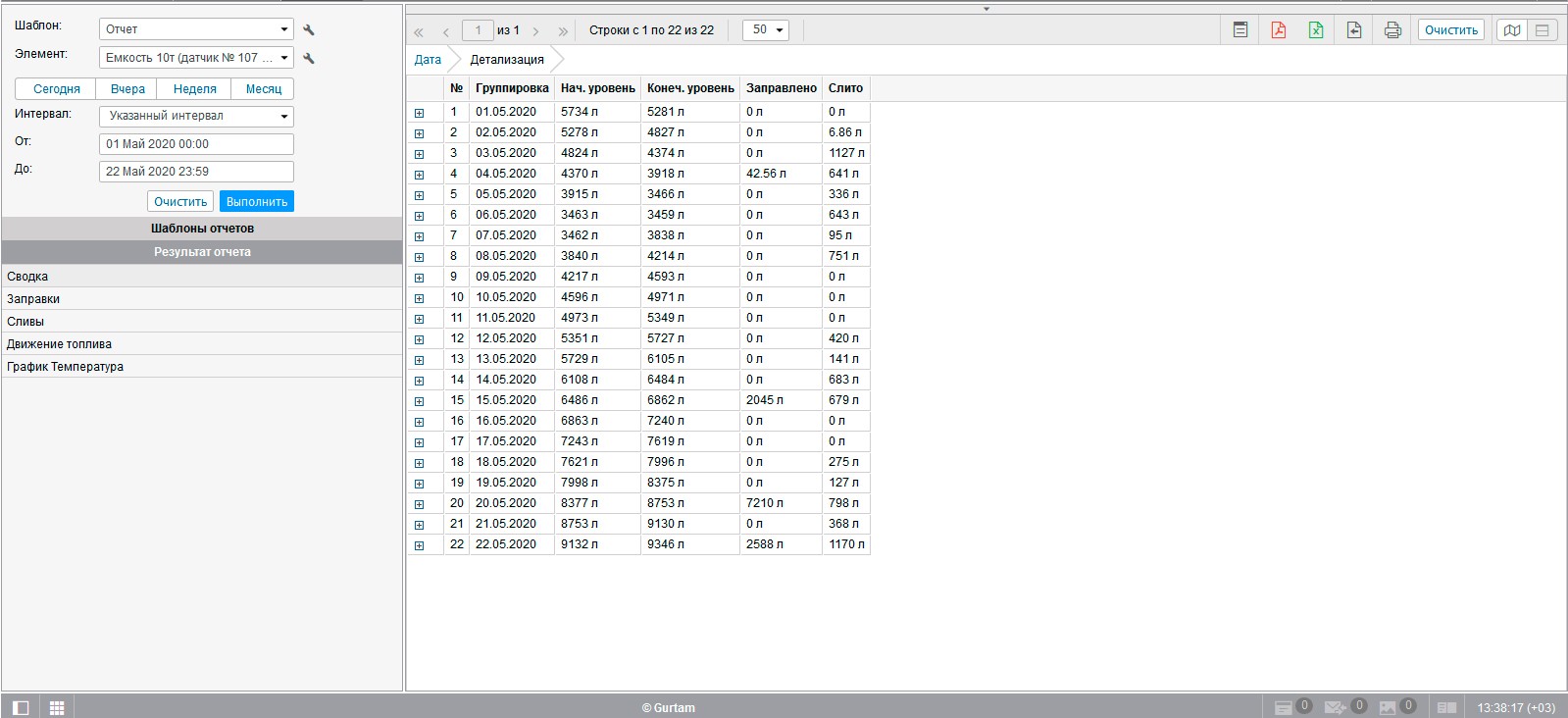

The TD-BLE sensors, installed on the tanks with total capacity of up to 10k, 16k and 25k liters are now constantly monitoring the fuel level inside and any manipulations with it. The collected level readings are then transmitted to the monitoring platform via the GPS tracker compatible with them.

All data collected on the platform is presented in clear and simple-to-read reports that comprise line graphs and tables using which it is easy to control what is going on with the fuel inside the tanks. Any fuel drain or dispensing can be compared with the fuel level readings collected on particular vehicles or machinery units that make up the company's fleet. Tractors, harvesters, trucks and lighter vehicles are also fitted with telematics devices and fuel in their tanks is also closely monitored.

The dispatches and the management of Mikhaylovsky Rayagrosnab can access the data on any tanks at any point. Such data includes:

- Fillings and drains

- Fuel level before and after each filling/drain

This helps the company:

- Monitor any manipulations with fuel on any particular vehicle

- Control the fuel consumption across the fleet

- Analyze the efficiency of fuel use

- Quickly find out about any discrepancies

- Prevent fuel theft attempts

- Promote discipline among employees

Results

“TD-BLE has enabled us to meet all customer’s requirements. Mikhaylovsky Rayagrosnab's management now has a tool for high-precision monitoring of fuel in the stationary tanks. This way the company can optimize its costs, avoid inefficient use of fuel and prevent unsanctioned manipulations by its employees.

This results, in general improvement of the financial performance and responsibility. Without any doubt, all this increases the company’s profitability and contributes to its development.

Implementation of wireless solutions shows the company’s innovative approach and enables it find even wider application of the precision agriculture concept in its processes,” comments Ruslan Zinnurov, the CEO at DAGAMA.