Application of Sokol-M weather station to optimize the crop spraying consumption

Country: Russia, Volga Federal District, Republic of Tatarstan

Industry: agriculture, crop production

Client: "KMP" company

Equipment: weather station "Sokol-M"

Specifics of the company's work

"KMP" company specializes in integrated solutions for animal breeding, including high-quality feed. When performing agricultural work, any agricultural enterprise inevitably faces the issues all agricultural producers are familiar with.

First of them is the high costs of the spraying crops with plant care chemicals, fertilizers and herbicides. In order for this process to be effective, it is necessary to strictly observe the procedural standards. For example, the wind speed should not exceed 5 m/s. A speed increase by just 1 m/s results in a 10 % reduction of the spraying efficiency and by 3 m/s increase - in a 30 % loss. The spraying costs an average amount to 50 USD/Hectar, whereas the area that a sprayer covers reaches 200 Hectars per day.

A farm with an area of 10 000 Hectars usually has 6-8 spraying units working simultaneously. Thus, the costs of chemical agents and fertilizers consumed daily rise up to 60 000 USD. An increase in wind speed of mere 1m/s leads to the losses of almost 6 000 USD per day.

Tasks

In order to increase the efficiency of agricultural operations, KMP was looking for a reliable tool that would help reduce the consumption of fertilizers, pesticides and other chemicals.

In addition to monitoring of the quality of soil and plant spraying, it was necessary to implement an equipment that would help reduce the influence of weather conditions on the yields and improve work planning.

The solution

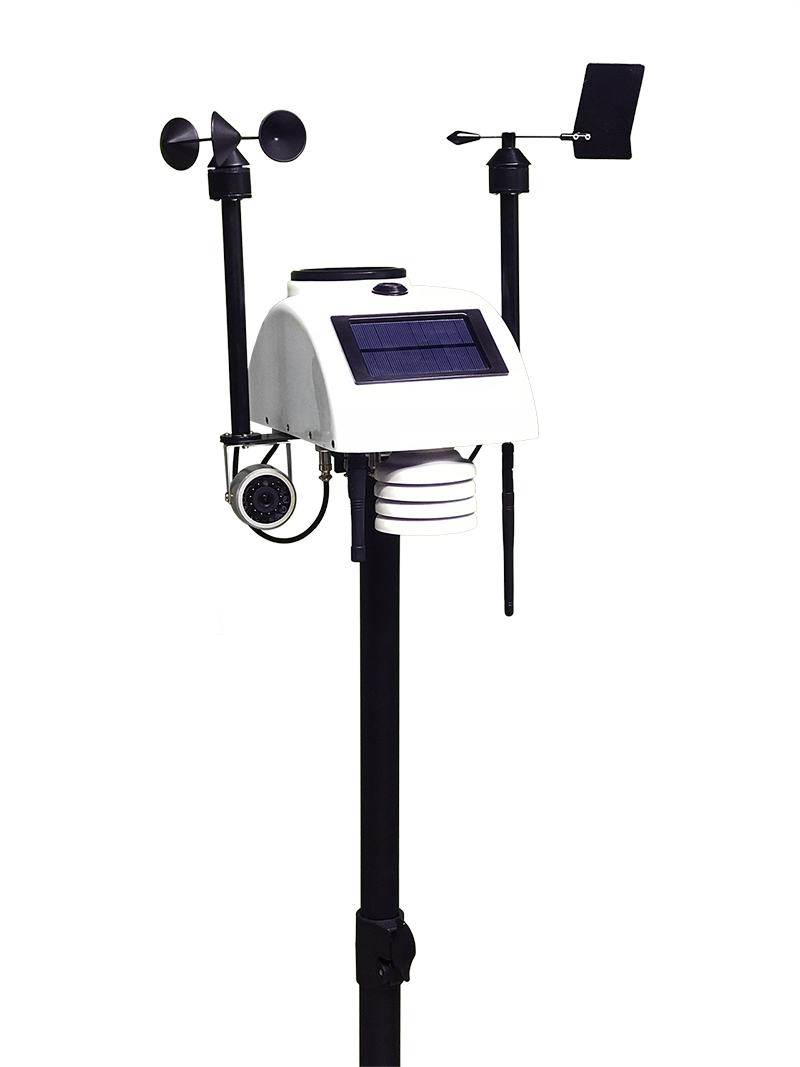

After a lot of time spent comparing products by different manufacturers, KMP company opted for Sokol-M – a professional autonomous weather station by Escort Monitoring Systems. The device capable of measuring:

- air temperature,

- relative air humidity,

- speed and direction of wind,

- atmospheric pressure,

- precipitation size and intensity,

- UV index,

- soil temperature and humidity.

Thanks to LoRa wireless technology implemented in Sokol-M stations, additional equipment (soil moisture and temperature sensors, leaf moisture sensors) placed within the 5 km range (3 miles) can be connected to the device as well. A web camera built into the weather station helps quickly track growth stages, prevent plant diseases and monitor the general situation at sites.

How it works. Example

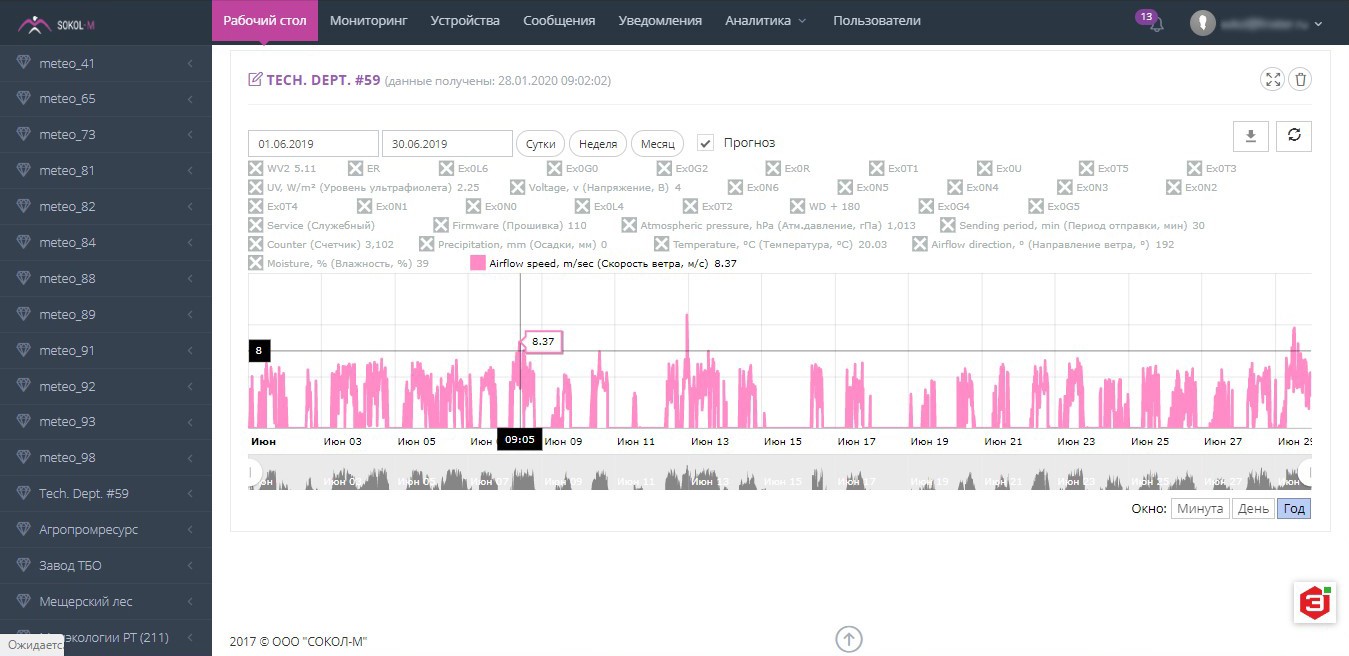

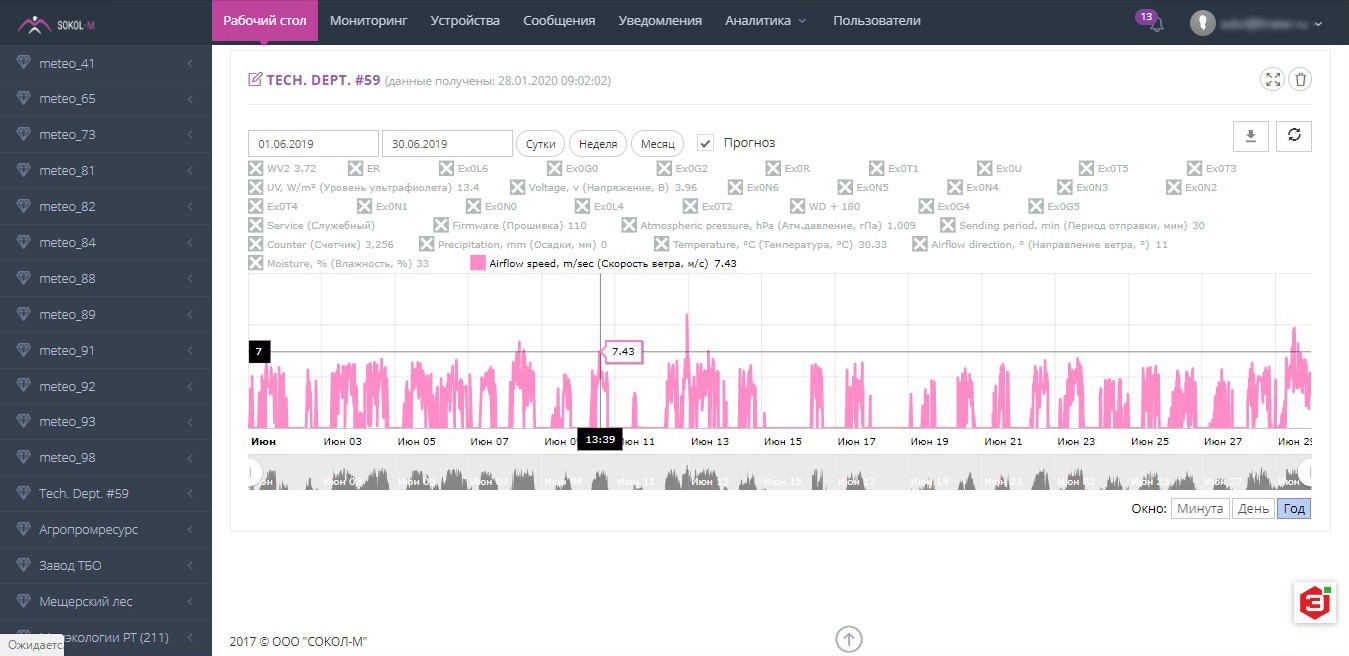

Screenshots from the remote control program show a weather station as it captures gusts of wind three times over a certain period of time.

Wind gusts in this example are more than 5 m/s, which means that the spraying process will not be effective and will result in losses.

Results

With "Sokol-M" installation, "KMP" have permanent access to information about weather conditions, can monitor the consumption of the chemicals and fertilizers as well as respond quickly to any urgencies. The data received from the weather station is stored on a designated cloud service sokolmeteo.com, which gives access to the analytics on the growth process, helps better plan field works and stores the data. By preventing inexpedient spraying activities only, the company saves up to 6 000 USD per day.

Thus, the investment in the weather station has paid off in just 1 day!

Further plans

The customer intends to install more Sokol-M stations at all facilities and use meteorological control data for in-depth business analysis of production processes.

This way KMP aims to increase the yield up to 8 tons in 2020.