Escort DB-2 sensors improve the efficiency and quality of harvesters' work.

Country: Russia, SFD, Kemerovo region, Tisul village

Industry: agriculture

Year: 2019

Client: "Resource" Ltd.

Integrator: "Argus" LLC

Task

"Resource" agricultural company is engaged in cultivation of cereals, leguminous crops and oilseeds. The company uses PALESSE GS, Yenisei-950 and Don-1500 harvesters. Each of them is equipped with bunkers for grain harvesting with capacity from 5 to 6 m³.

In conditions of intensive field work, it was almost impossible to monitor the filling of each hopper, the performance of the equipment and the actions of the mechanic. The lack of local yield control often resulted in discrepancies in the calculation of the harvested crop.

In addition, there was always the possibility that the operator will report lower norm values and steals grain. That's why "Resource" LLC. needed tools for remote monitoring of harvesting on each unit of agricultural machinery.

Solution

In order to continuously monitor grain dynamics in the bunkers of harvesters, the integrator of agricultural control systems offered the " Resource" LLC. management to install "Escort DB-2" bulk level sensor to the machines. Escort DB-2 is a telematic device with a capacitive measuring principle that can monitor the filling and emptying of all bulk materials with humidity up to 25%.

The information captured by the sensor is transferred to the on-board GLONASS / GPS device and further visible in the software platform.

"Escort DB-2" bulk level sensor, as well as all products of "Escort" brand, can be easily integrated with other remote monitoring systems of transport and stationary objects. The equipment has a high degree of protection (IP67) and is resistant to severe temperature changes (-60 … +85°C), it can be used in all weather conditions and in all terrain.

Escort DB-2 installation

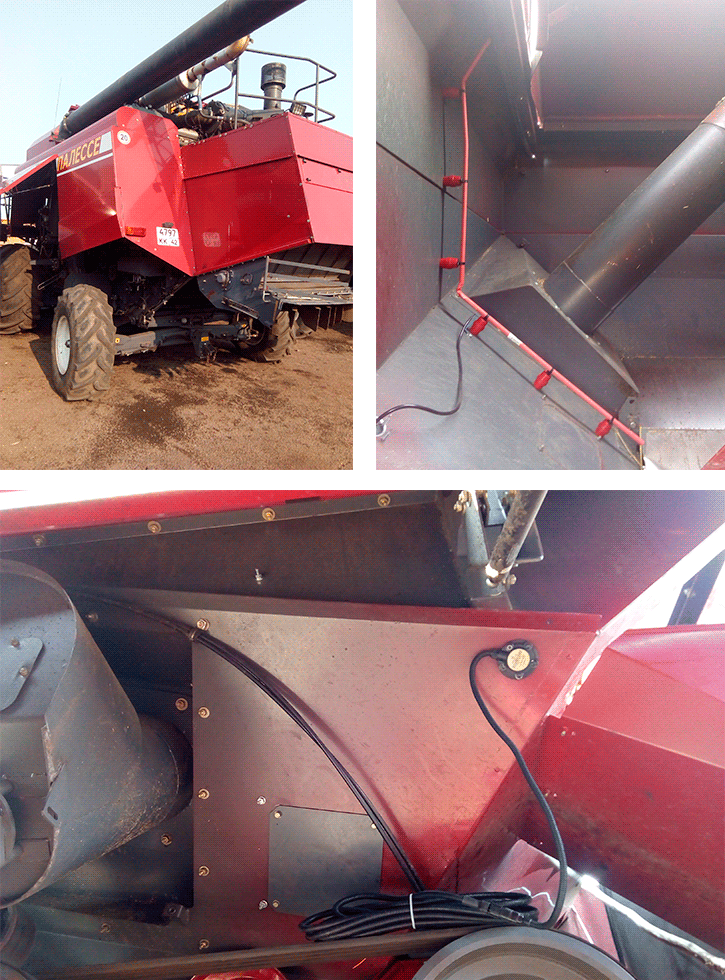

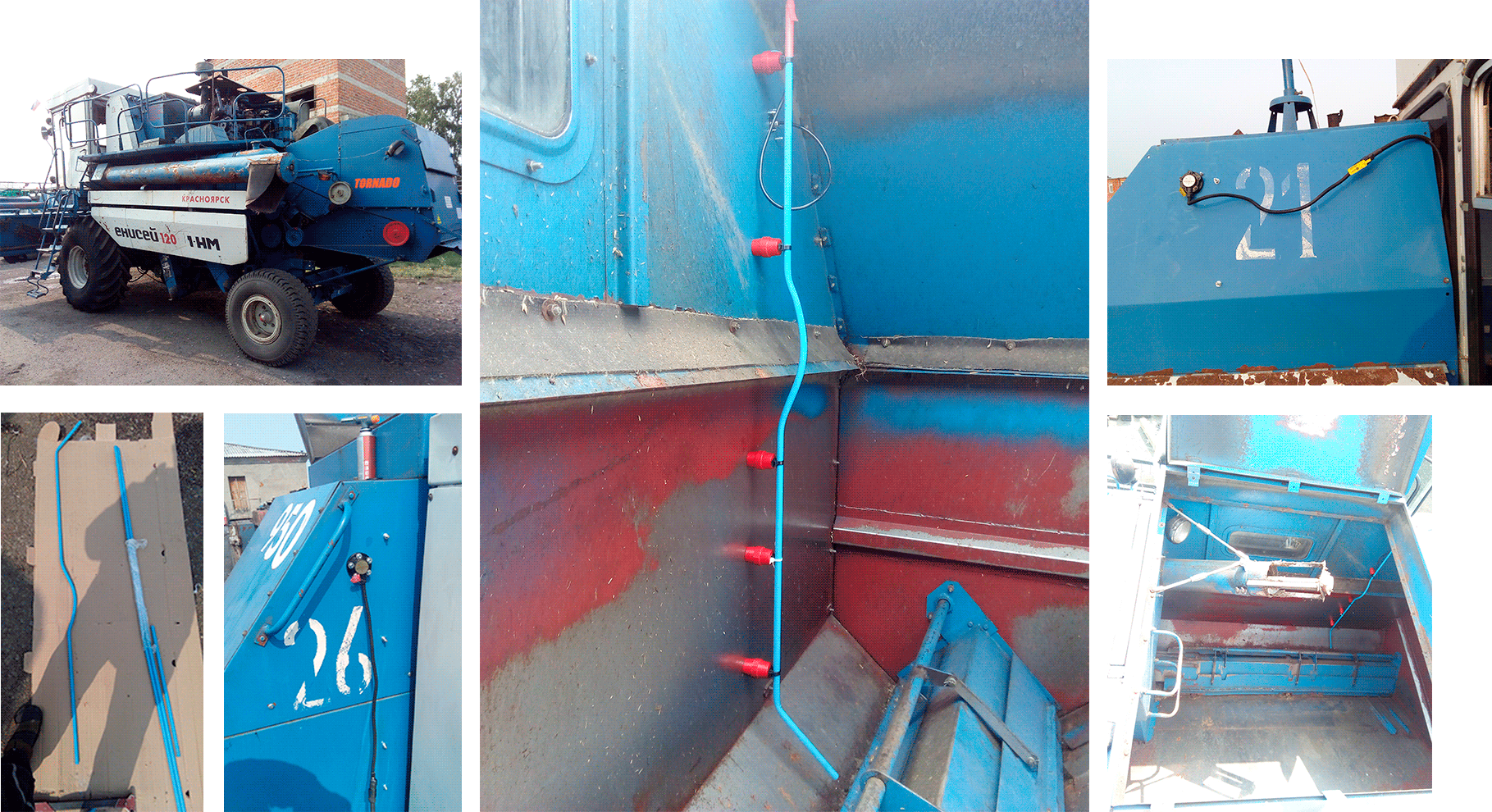

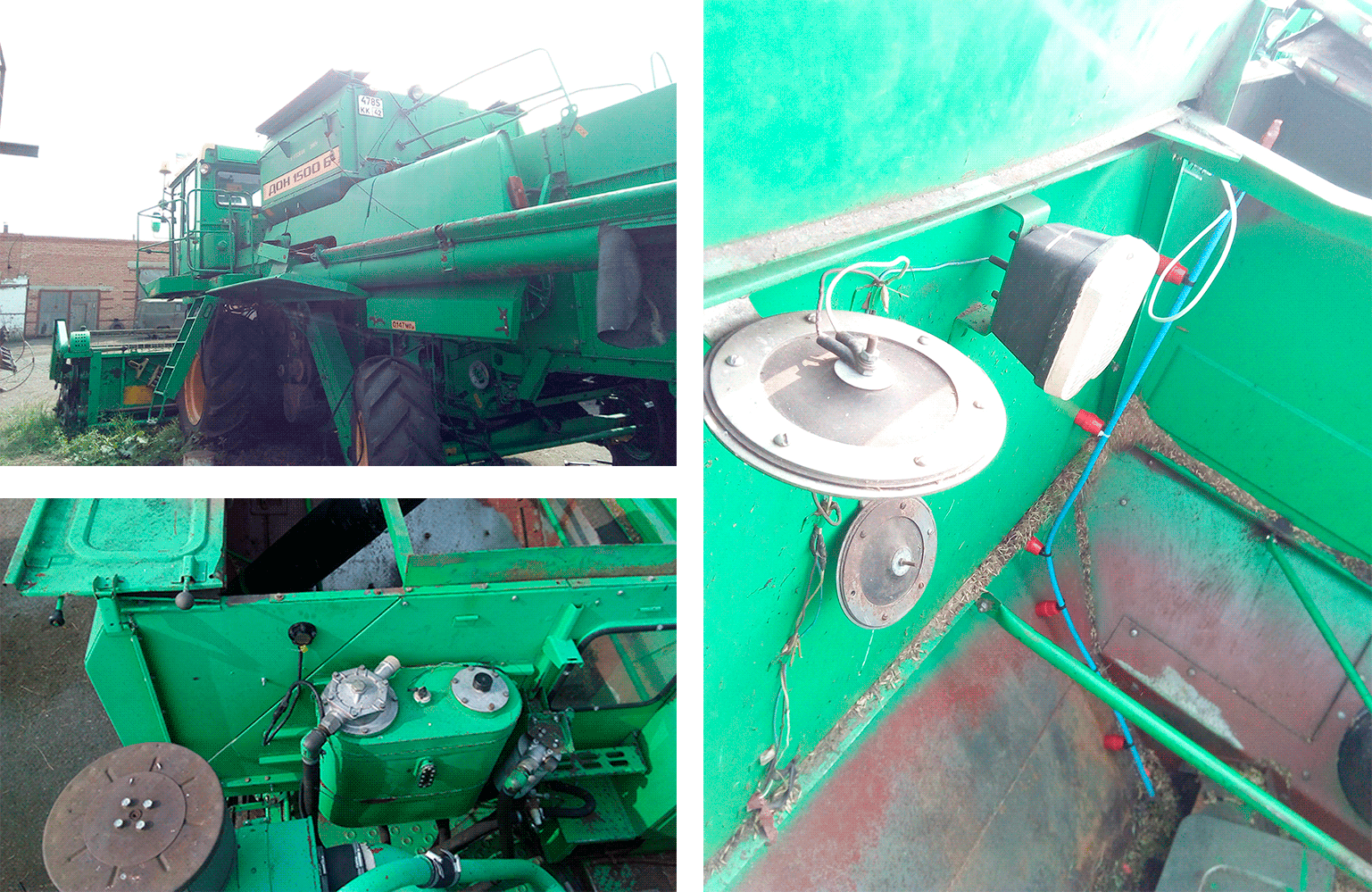

"Escort DB-2" bulk level sensors were installed on the walls of bunkers of all harvesters of "Resource" LLC . As the device is universal, specialists have not faced the problem of mounting on different models of machinery. These images show how PALESSE GS, Yenisei-950 and Don-1500 combines were equipped.

How does it work?

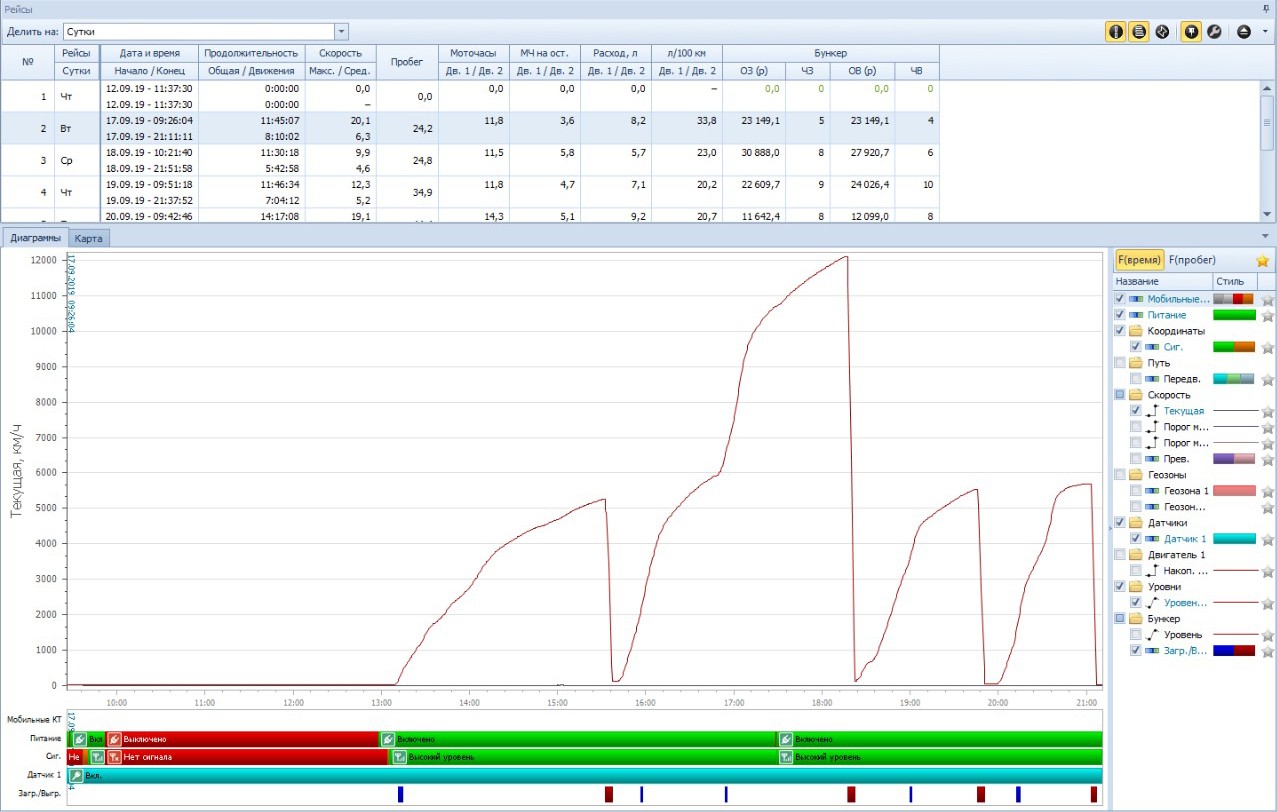

Sensors continuously detect changes in grain level dynamics. This information is immediately displayed online in the agricultural monitoring platform along with the dataabout other technical parameters. Users see summaries of bulk material loading/unloading volumes in each bunker and can analyze that data in relation to geofences, travel routes, motor-hours, speed, mileage, engine operation, etc. Information on the situation in each bunker is stored in the satellite tracking system database. The responsible persons can always view reports on the operation of an individual harvester or group of harvesters for specified periods of time. This makes it possible to check norms, identify problems in the operation of machinery and machine operators, and learn about unauthorised actions.

Result

Along with the installation of "Escort DB-2" sensors , "Resource" LLC received full control over the harvest on their fields. Thanks to accurate and prompt information about the grain level in the bunkers, the management can analyze the quality of harvesting, keep accurate records of volumes, prevent equipment breakdowns, negligence and theft, increase the efficiency of agricultural activities and increase profits.

Integrator’s review

For Resource LLC, the cost of implementing Escort DB-2 paid off almost immediately. At the very first harvest, thanks to sensors, it was discovered that in fact 6 bunkers are loaded and only 5 are unloaded. One "lost" bunker of wheat costs tens of thousands of rubles. Obviously, the cost of installing the DB-2 has justified itself.

Now no such case can be left without attention and any attempts at scams are stopped at the very bottom.