Fuel monitoring for better fleet management

TD-BLE helps a transportation company improve performance

Country: Odessa, Ukraine

Industry: transportation and logistics

Customer: transportation and haulage company

Integrator: MobiTeam company

Equipment: Wireless fuel level sensor Escort TD-BLE

Customer's objective: to monitor and control fuel consumption and vehicle operation

Until recently, the customer did not use any GPS solutions to monitor the fuel consumption on their vehicles despite having a huge fleet of those. However and most importantly, it was not clear what those solutions could be, exactly, and if they would be efficient. Therefore, the company’s management tasked the integrator with finding a reliable means that would make it possible to:

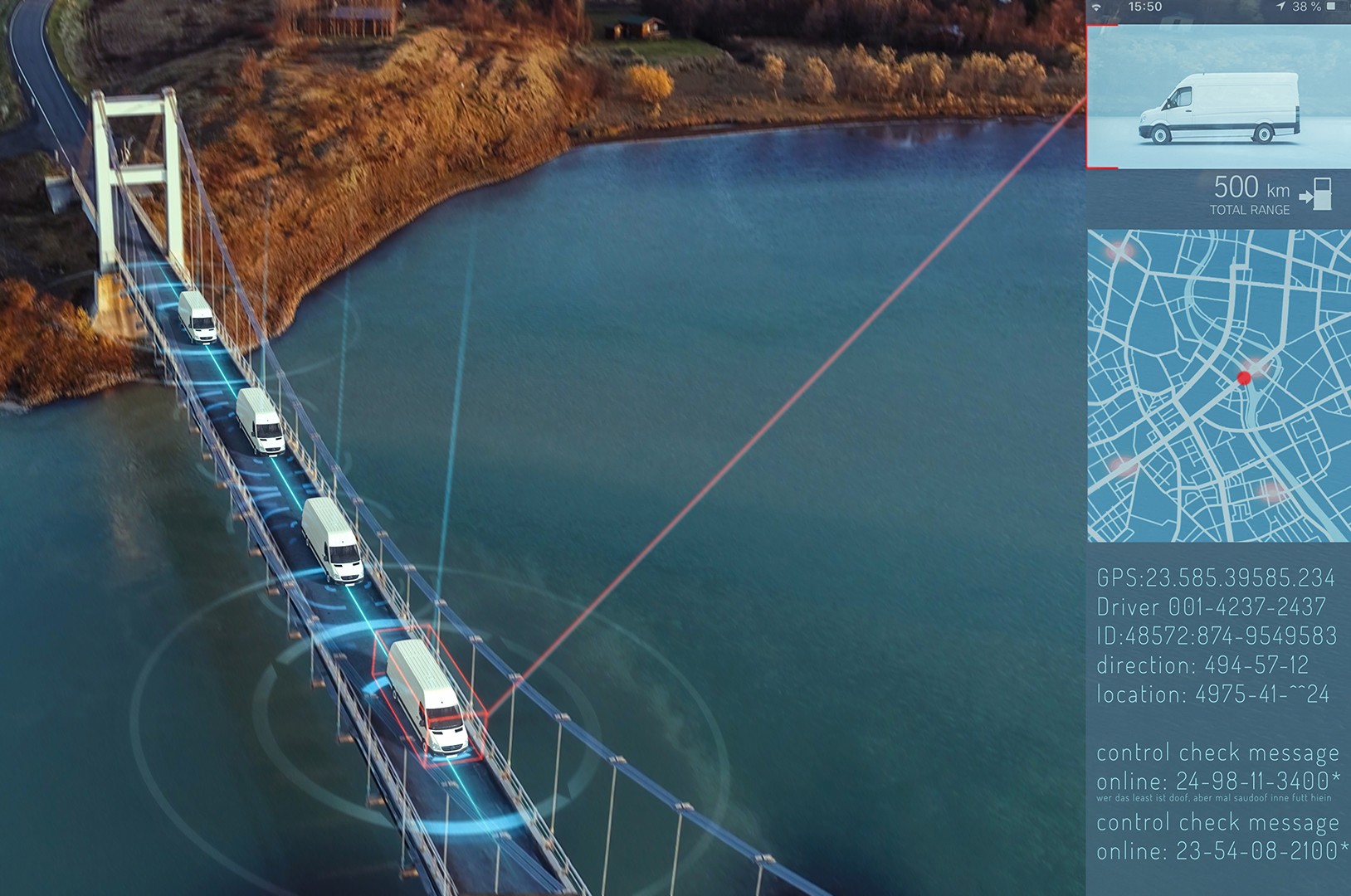

- track the geo-location of every vehicle;

- monitor the fuel consumption and several other parameters;

- keep record of any deviations from predetermined routes;

- keep track of the time spent in certain geo-zones;

- control time spent in loading and offloading points.

Solution

Being experts with a vast experience of implementing various M2M equipment and GPS monitoring systems, MobiTeam came up with a comprehensive solution that consisted of:

- Fitting every fleet unit with the BI 920 TREK trackers to have access to the data on geo-location, speed, stops, etc

- Connecting the GPS devices to the CAN bus of the vehicles to monitor such standard parameters as engine RPM and workload, the weight of the load, AdBlue level, etc

- Mounting the capacitive fuel level sensors TD-BLE on the tanks to control the fuel consumption, loadings and drainages

MobiTeam opted for the wireless FLS TD-BLE for a reason. After all, it is one of the most reliable devices that helps monitor the fuel consumption at minimal installation and maintenance costs. When mounting the sensor, one does not have to worry about the cabling and only needs a smartphone to configure the device.

TD-BLE also stands out for its battery life of several years, which is achieved thanks to the Bluetooth Low Energy technology. Additionally, the sensor is compatible with a vast range of GPS trackers and monitoring platforms.

Installing fuel monitoring equipment

First, the integrator’s team fitted every fleet unit with the BI 920 TREK devices, connecting them to the vehicles’ OBDs. They also took care of the transmission of the data on the truck’s autonomous heaters to the monitoring system.

Then, the fuel level sensors TD-BLE were mounted on every tank and connected to the BI 920 TREK trackers. Every sensor’s data is thus transmitted, along with other data, to the GPS device and - subsequently - to the monitoring platform of the customer’s choosing.

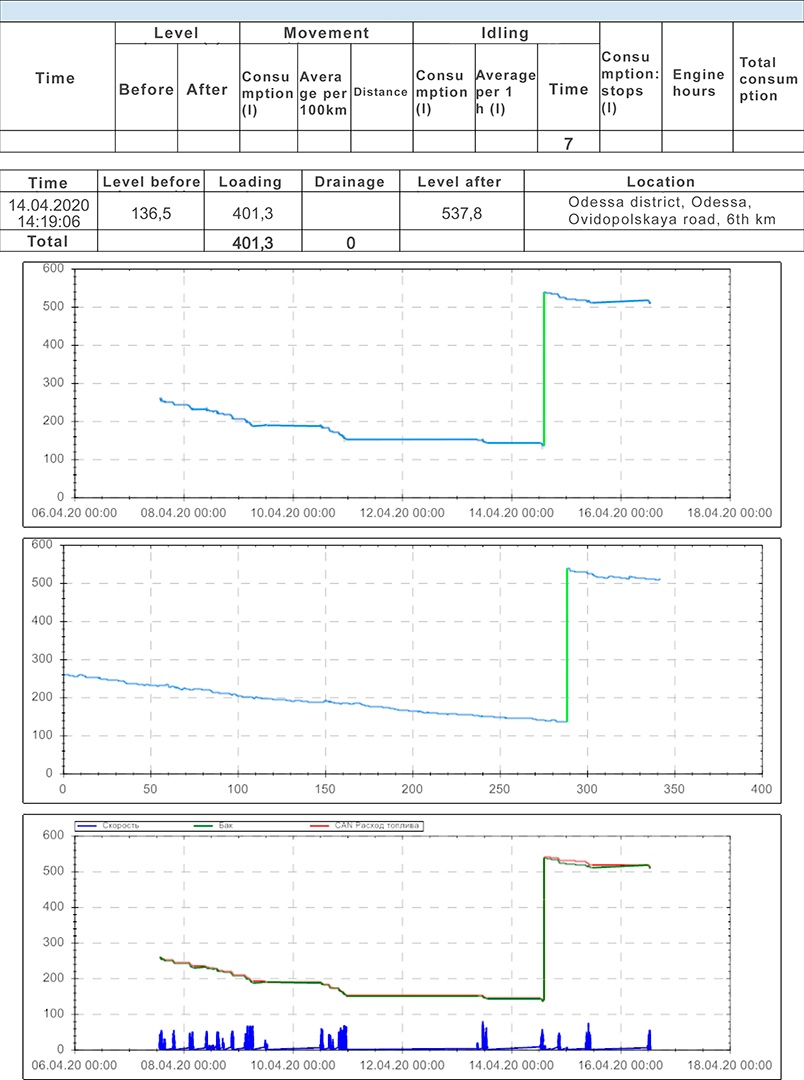

On the platform, the operators can access any information about the fuel consumption coming from both the CAN bus of a vehicle and the TD-BLE sensor(s) installed on it. Thus, the customer now can control the actual fuel consumption of each unit with 99% precision.

Thanks to the capacitive FLS, it is now easy to find out about any attempt to steal fuel directly from the tank or from the fuel return pipe.

Results

“By implementing the mentioned GPS-tracking system along with the up-to-date telematics devices, we have been able to cover all the customer's needs as to monitoring fuel consumption and vehicle operation. Now the customer can control how their assets are operated both in real time and by means of analytical reports. The customer can access the data on their vehicles at any given time via a desktop, web and mobile application. The installed equipment, including the TD-BLE sensors, provides efficient means to monitor the fleet and, as a result, improve the performance and reduce the costs,” comments the integrator.